The texture of ice cream is a delicate dance between science and artistry, where the control of ice crystals plays the starring role. For centuries, ice cream makers have sought the perfect balance—a creamy, smooth consistency that melts luxuriously on the tongue. The secret lies not just in the ingredients but in the precise manipulation of ice crystal formation. Too large, and the dessert becomes grainy; too small, and it loses its satisfying richness. Mastering this balance is what separates mediocre ice cream from the extraordinary.

At its core, ice cream is a complex colloidal system. It consists of air bubbles, fat globules, and a network of ice crystals suspended in a sugary syrup. The interplay between these elements determines the final texture. Among them, ice crystals are the most critical factor influencing smoothness. When ice cream is churned and frozen, water molecules begin to form crystalline structures. The size and distribution of these crystals dictate whether the ice cream will feel velvety or coarse on the palate.

The Science Behind Crystal Formation

Ice crystal growth is governed by thermodynamics and kinetics. During freezing, the rate at which heat is removed from the mixture affects how quickly crystals form. Rapid freezing, such as in industrial blast freezers, encourages the creation of numerous tiny crystals. In contrast, slower freezing leads to fewer, larger crystals. This is why homemade ice cream, often frozen in a standard kitchen freezer, can sometimes develop an icy texture compared to commercial varieties.

Another key factor is recrystallization—the process by which small crystals melt and reform into larger ones over time. This phenomenon occurs even in subzero temperatures due to temperature fluctuations during storage. Each time the ice cream partially thaws and refreezes, the crystals grow, degrading the texture. Stabilizers like guar gum or carrageenan are often added to minimize this effect by binding water molecules and restricting their movement.

The Role of Ingredients in Crystal Control

Not all ice cream bases are created equal. The composition of the mixture profoundly impacts crystal formation. Sugar, for instance, doesn’t just sweeten—it lowers the freezing point of water, creating a softer texture. However, too much sugar can make the ice cream overly soft or even syrupy. Dairy fats, on the other hand, coat ice crystals, physically preventing them from growing too large. This is why high-fat ice creams often have a creamier mouthfeel.

Egg yolks, a staple in custard-based ice creams, introduce emulsifiers like lecithin that help disperse fat molecules evenly. This uniform distribution creates a finer crystal structure. Meanwhile, proteins from milk and eggs act as stabilizers, forming a protective matrix around ice crystals. Even the type of sweetener matters: corn syrup, with its long-chain sugars, interferes with crystal growth more effectively than table sugar, resulting in a smoother product.

Technological Advances in Ice Cream Production

Modern ice cream manufacturers employ cutting-edge techniques to optimize texture. Continuous freezers, for example, allow for ultra-fast freezing while simultaneously incorporating air. This process, known as overrun, introduces microscopic air cells that disrupt ice crystal networks, yielding a lighter consistency. Some premium brands even use liquid nitrogen, which freezes the mixture so quickly that crystals barely have time to form, producing an exceptionally smooth result.

Another innovation is the use of ultrasonic homogenization. By subjecting the ice cream base to high-frequency sound waves, manufacturers can break down fat clusters and ice crystals into minuscule particles. This technology, once reserved for pharmaceuticals, is now finding its way into gourmet ice cream production. Similarly, high-pressure processing (HPP) alters the physical properties of water, enabling freezing at temperatures slightly above normal, which reduces crystal size.

The Human Element in Texture Perfection

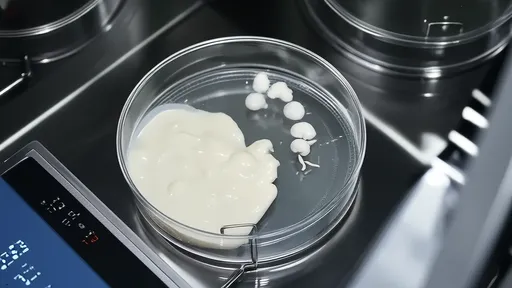

Despite technological advancements, the craft of ice cream making remains deeply human. Artisan producers rely on experience and intuition to judge when a batch has reached optimal crystallization. The timing of churning, the temperature of ingredients, and even the ambient humidity all play roles that machines cannot fully account for. This tactile knowledge—passed down through generations—often produces textures that industrial methods struggle to replicate.

Storage and serving conditions also influence the final experience. Ice cream stored at extremely low temperatures becomes too hard, while slightly warmer serving temperatures allow its full texture to shine. Professional tasters describe great ice cream as having "coldness without iciness," a quality achieved only through meticulous control of every variable in the process.

The Future of Ice Crystal Mastery

As food science progresses, new frontiers in crystal control are emerging. Researchers are experimenting with ice-structuring proteins derived from Arctic fish or winter wheat—natural compounds that inhibit crystal growth at molecular levels. Meanwhile, plant-based alternatives are challenging traditional dairy formulations, requiring novel approaches to texture management. The quest for the perfect scoop continues to evolve, blending ancient techniques with space-age technology.

Ultimately, ice cream texture is a testament to human ingenuity. What began as a simple frozen treat has become a sophisticated study in physical chemistry. Every spoonful represents countless hours of research, experimentation, and passion—all dedicated to that fleeting moment of creamy perfection. In the world of frozen desserts, controlling ice crystals isn’t just science; it’s the essence of delight.

By /Jul 14, 2025

By /Jul 14, 2025

By /Jul 14, 2025

By /Jul 14, 2025

By /Jul 14, 2025

By /Jul 14, 2025

By /Jul 14, 2025

By /Jul 14, 2025

By /Jul 14, 2025

By /Jul 14, 2025

By /Jul 14, 2025

By /Jul 14, 2025

By /Jul 14, 2025

By /Jul 14, 2025

By /Jul 14, 2025

By /Jul 14, 2025

By /Jul 14, 2025

By /Jul 14, 2025