The humble steamed bun, a staple in many Asian cuisines, holds within its fluffy interior a fascinating scientific phenomenon. Behind its deceptively simple appearance lies a complex interplay of physics and chemistry that gives rise to those characteristic air pockets we've all come to love. The formation of these cavities isn't accidental - it's the direct result of carefully controlled steam expansion during the cooking process, a culinary alchemy that transforms dense dough into light, airy perfection.

When raw dough enters the steamer, it carries with it millions of microscopic air bubbles trapped during the mixing and kneading process. These tiny voids become the nucleation sites for what will eventually grow into the bun's distinctive honeycomb structure. As heat penetrates the dough, two simultaneous transformations occur: the moisture within turns to vapor, while the gluten proteins surrounding these bubbles begin to set into their final configuration. The expanding steam pushes against these elastic gluten walls, stretching them like miniature balloons.

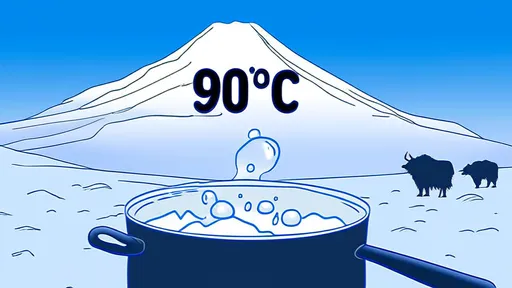

The critical moment comes when internal temperatures reach approximately 60°C (140°F), the point at which starch gelatinization begins. This process allows the dough to transition from a pliable mass to a firm structure capable of maintaining its shape. However, the steam continues expanding well beyond this temperature, creating increasing internal pressure. The gluten network must be strong enough to contain this pressure without rupturing prematurely, yet elastic enough to allow for sufficient expansion to create the desired texture.

Professional bakers understand that the rate of heating significantly impacts pore formation. Too rapid heating causes explosive vaporization that can tear the gluten matrix, resulting in large, irregular holes and potential collapse. Conversely, insufficient heat leads to incomplete expansion and a dense, gummy texture. The ideal steaming environment maintains consistent temperature and humidity, allowing for gradual, even expansion throughout the entire bun.

Water content plays an equally crucial role in pore development. Dough with inadequate hydration fails to produce sufficient steam for proper expansion, while overly wet dough lacks the structural integrity to maintain bubbles. The perfect balance creates enough vapor to form numerous small, uniform cells while leaving the walls between them thin but unbroken. This delicate equilibrium explains why precise measurements matter in professional kitchens, where a few percentage points difference in water content can dramatically alter the final product.

The chemistry of fermentation adds another layer of complexity to this process. Yeast produces carbon dioxide during proofing, creating additional gas pockets that contribute to the overall structure. These biological byproducts interact with the steam-generated voids, sometimes merging to form larger chambers. The duration and temperature of proofing therefore become critical variables - under-proofed dough lacks sufficient gas for proper texture, while over-proofed dough may have weakened gluten unable to withstand steam pressure.

Modern food science has revealed that pore distribution follows predictable patterns based on dough composition and cooking methods. X-ray microtomography studies show that commercial steamers producing constant, directional heat flow create more vertically aligned pores compared to traditional bamboo steamers with their circulating heat patterns. This microscopic architecture affects not just appearance but also mouthfeel and flavor release, as the surface-area-to-volume ratio changes with pore size and orientation.

Temperature gradients within the steaming chamber account for variations in pore structure between a bun's exterior and interior. The outer layers, exposed to direct steam, experience faster protein denaturation and starch gelatinization, forming a denser crust with smaller cells. Meanwhile, the core benefits from slower, more even heating, allowing for maximum expansion before the structure sets. This natural variation explains why perfectly steamed buns exhibit different textures from center to edge.

The phenomenon of retrogradation - starch molecules recrystallizing after cooling - further modifies the pore structure post-steaming. As the bun cools, some shrinkage occurs, but the basic cellular framework remains intact. This retrogradation actually enhances the desirable chewiness of quality steamed buns, proving that the science continues even after removal from heat. The interplay between these dynamic processes demonstrates why steaming, among all cooking methods, produces such uniquely textured bread products.

Industrial food engineers have applied these principles to develop specialized equipment that optimizes pore formation. Computer-controlled steam injection systems now regulate pressure and humidity with precision impossible in traditional setups. Some advanced steamers even incorporate ultrasonic mist generators to create finer water droplets that penetrate dough more evenly, resulting in unprecedented consistency in pore size and distribution.

Home cooks can observe these scientific principles in action through simple experiments. Comparing buns steamed at different temperatures, or with varying proofing times, makes the cause-and-effect relationships visibly apparent. The difference between dough made with bread flour versus all-purpose flour becomes strikingly obvious when examining their respective pore structures - the higher gluten content creating more numerous, smaller cells capable of withstanding greater steam pressure.

This intricate dance between water, heat, and proteins explains why steamed buns have remained essentially unchanged for centuries - the process represents an optimal balance of physical forces that human ingenuity discovered long before modern science could explain it. From street vendors to high-end restaurants, chefs continue to rely on these fundamental principles, proving that great food often rests on a foundation of impeccable science, even when that science operates invisibly beneath a soft, white surface.

By /Jul 14, 2025

By /Jul 14, 2025

By /Jul 14, 2025

By /Jul 14, 2025

By /Jul 14, 2025

By /Jul 14, 2025

By /Jul 14, 2025

By /Jul 14, 2025

By /Jul 14, 2025

By /Jul 14, 2025

By /Jul 14, 2025

By /Jul 14, 2025

By /Jul 14, 2025

By /Jul 14, 2025

By /Jul 14, 2025

By /Jul 14, 2025

By /Jul 14, 2025

By /Jul 14, 2025