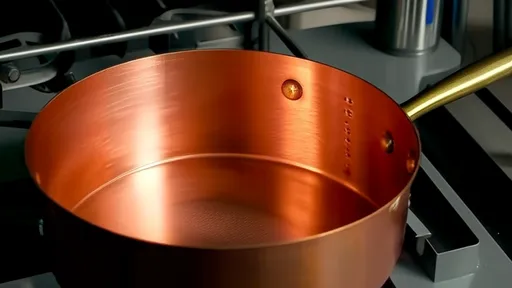

For centuries, professional chefs and home cooks alike have prized copper cookware for its exceptional performance. The secret lies in copper's remarkable ability to conduct heat efficiently and evenly across its surface. Unlike other common cookware materials, copper responds almost instantly to temperature changes, providing precise control that's essential for delicate sauces and perfectly seared meats.

At the atomic level, copper's crystalline structure contains a "sea of electrons" that can move freely through the metal lattice. When heat is applied to one area of a copper pan, these mobile electrons rapidly transfer thermal energy throughout the entire cooking surface. This phenomenon explains why copper demonstrates thermal conductivity nearly twice that of aluminum and about eight times greater than stainless steel.

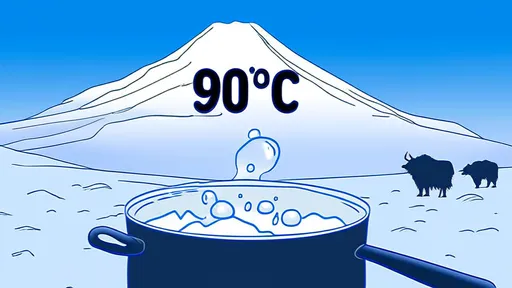

The molecular advantage of copper becomes particularly apparent when comparing temperature distribution. While an iron or stainless steel pan might develop hot spots that burn food in certain areas while undercooking others, copper maintains remarkable temperature uniformity. This even heating stems from copper's ability to redistribute thermal energy at speeds approaching 400 watts per meter-kelvin at room temperature.

Cooking with copper allows for immediate response to heat adjustments. When you reduce the flame under a copper saucepan, the pan's temperature drops almost as quickly as the heat source changes. This responsiveness gives chefs unparalleled command over delicate processes like melting chocolate or preparing hollandaise sauce, where precise temperature control makes the difference between success and failure.

Modern copper cookware often features a stainless steel or tin lining that combines the best properties of different materials. While pure copper reacts with acidic foods, these linings create a safe cooking surface while preserving copper's thermal benefits. The layered construction demonstrates how material science has evolved to enhance traditional cookware designs.

The thickness of copper cookware significantly impacts its performance. Professional-grade copper pans typically measure between 2.3 and 3 millimeters thick - substantial enough to maintain heat capacity while still allowing quick temperature adjustments. This optimal thickness creates what chefs call "heat memory," where the pan retains enough thermal energy to recover quickly when food is added, yet remains responsive to stove-top changes.

From a physics perspective, copper's reddish-orange color actually contributes to its cooking efficiency. The metal's surface emits infrared radiation in a spectrum that transfers heat particularly well to food. This radiant heat transfer complements the conductive properties, creating a multi-modal heating system that no other common cookware material can match.

While copper cookware requires more maintenance than stainless steel or cast iron, many culinary professionals consider the extra care worthwhile. The immediate feedback from copper allows experienced cooks to judge temperature by the pan's appearance and behavior, developing an intuitive understanding that's difficult to achieve with other materials. This connection between cook and cookware represents the intersection of science and culinary art.

Modern thermal imaging studies have visually demonstrated copper's superiority in heat distribution. Infrared cameras show copper pans maintaining temperature differentials of less than 5°C across their surfaces during cooking, while other materials might show variations of 30°C or more. This scientific validation confirms what chefs have known empirically for generations.

The culinary applications of copper's thermal properties extend beyond stovetop cooking. Copper bowls are preferred for whipping egg whites because the metal's conductivity helps stabilize the protein structure. Similarly, copper molds are traditional for preparing delicate desserts like crème brûlée because they transfer heat so evenly during baking.

As consumers become more sophisticated about kitchen tools, understanding the materials science behind cookware gains importance. While copper represents a significant investment, its lifetime of superior performance and cooking precision justifies the cost for serious cooks. The metal's natural beauty, combined with its unparalleled functionality, ensures copper's continued status as the gold standard of professional kitchens.

Recent advances in materials engineering have led to copper-infused cookware that offers some thermal benefits at lower price points. However, these composite materials cannot fully replicate the performance of solid copper. The density and purity of traditional copper construction create a thermal response that composites struggle to match, particularly for techniques requiring rapid temperature changes.

The environmental aspect of copper cookware adds another dimension to its appeal. As a naturally occurring element, copper is fully recyclable without degradation of quality. Well-maintained copper pans often become family heirlooms, passing through generations while maintaining their cooking performance - a sustainability factor that disposable cookware cannot approach.

Understanding the science behind copper's heat conduction allows cooks to make informed decisions about their kitchen tools. While copper may not be necessary for every cooking task, its unique properties make it indispensable for certain culinary techniques. From the physics of electron movement to the practicalities of sauce preparation, copper cookware represents a perfect marriage of scientific principles and culinary tradition.

By /Jul 14, 2025

By /Jul 14, 2025

By /Jul 14, 2025

By /Jul 14, 2025

By /Jul 14, 2025

By /Jul 14, 2025

By /Jul 14, 2025

By /Jul 14, 2025

By /Jul 14, 2025

By /Jul 14, 2025

By /Jul 14, 2025

By /Jul 14, 2025

By /Jul 14, 2025

By /Jul 14, 2025

By /Jul 14, 2025

By /Jul 14, 2025

By /Jul 14, 2025

By /Jul 14, 2025