The art of creating perfect mayonnaise lies in understanding the delicate dance of fat emulsification. This creamy condiment, beloved across cultures, achieves its signature texture through a complex interplay of chemistry and technique. At its core, mayonnaise represents one of cooking's most fascinating scientific phenomena - the transformation of separate liquids into a stable, homogeneous mixture that defies their natural tendency to separate.

The foundation of mayonnaise stability begins with the emulsion itself. When oil and water-based ingredients like lemon juice or vinegar combine under proper conditions, they form what scientists call a colloidal dispersion. Tiny oil droplets become suspended in the aqueous phase, creating the characteristic thick texture we associate with quality mayonnaise. The key to maintaining this suspension lies in preventing the droplets from coalescing and separating back into distinct layers.

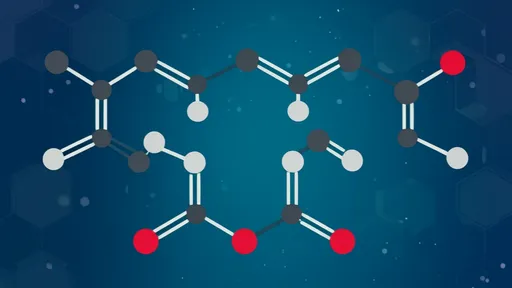

Egg yolk emerges as the unsung hero in this culinary alchemy. Rich in phospholipids and proteins, the yolk contains powerful emulsifiers that position themselves at the oil-water interface. Lecithin molecules, with their water-loving and fat-loving ends, act as molecular bridges between the two normally incompatible substances. These natural emulsifiers reduce surface tension and create a protective barrier around each oil droplet, preventing them from merging together.

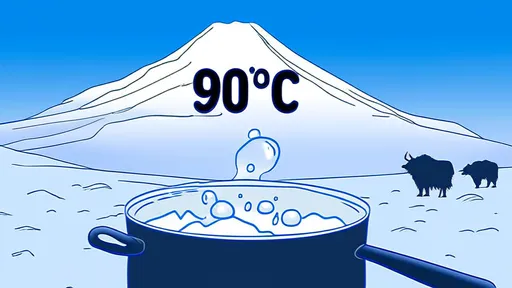

Temperature control plays a subtle but crucial role in emulsion stability. While many home cooks focus solely on ingredient ratios, professionals understand that the thermal environment affects everything from viscosity to molecular interactions. Cold ingredients can hinder proper emulsification, while excessive warmth may cause the emulsion to break. The ideal temperature range allows for optimal molecular movement without compromising structural integrity.

The choice of oil significantly impacts both texture and stability. Oils with higher viscosity and specific fatty acid profiles tend to create more stable emulsions. Many commercial producers select oils based on their crystallization behavior and melting points, as these characteristics influence the mayonnaise's mouthfeel and resistance to temperature fluctuations during storage and transport.

Acidic components serve multiple functions beyond flavor enhancement. Vinegar or lemon juice lowers the pH, which affects protein behavior in the egg yolk. This acidic environment helps denature proteins, making them more effective at stabilizing the oil droplets. Additionally, the lowered pH creates an inhospitable environment for microbial growth, extending the product's shelf life while maintaining food safety standards.

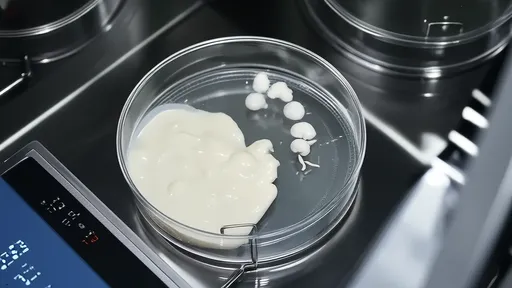

Modern food science has revealed that emulsion stability depends on droplet size distribution. Smaller, more uniform oil droplets create a tighter matrix that resists separation. This explains why commercial mayonnaise, produced with high-shear mixing equipment, often demonstrates greater stability than homemade versions. The mechanical energy input directly correlates with droplet size reduction and emulsion quality.

The addition timing of various ingredients follows principles grounded in colloidal chemistry. Seasonings and flavorings often get incorporated at specific phases to optimize their distribution without interfering with the emulsion process. Salt, for instance, can affect protein solubility and should be added with consideration to its impact on the overall system.

Stabilizers in commercial mayonnaise formulations work synergistically with the natural emulsifiers from egg yolk. Ingredients like xanthan gum or modified starches create a network that physically prevents oil droplets from moving and coalescing. These hydrocolloids increase the continuous phase's viscosity, effectively locking the dispersed oil droplets in place.

Oxidation represents a constant threat to emulsion stability. Exposure to light and oxygen can degrade both the oil and egg components, leading to flavor deterioration and potential emulsion breakdown. Packaging technology has evolved to address these challenges, with light-blocking containers and oxygen-scavenging materials becoming industry standards for premium products.

The rheological properties of mayonnaise - how it flows and deforms under stress - tell an important story about its quality. Perfect mayonnaise should exhibit pseudoplastic behavior, becoming less viscous when sheared (as during spreading) but maintaining sufficient thickness at rest. This delicate balance comes from precisely controlled emulsion characteristics and proper formulation.

Industrial production has refined mayonnaise stability through controlled processing parameters. Factors like mixing speed, duration, and sequence get carefully optimized to achieve consistent results at scale. The transition from batch processing to continuous production systems has allowed for even greater control over emulsion quality.

Consumer preferences continue to drive innovation in mayonnaise stability. The growing demand for reduced-fat versions presents unique challenges, as removing oil alters the fundamental emulsion dynamics. Food scientists have developed novel approaches using alternative texturizers and emulsification techniques to mimic the mouthfeel of traditional mayonnaise while meeting nutritional guidelines.

Microbial stability remains a critical consideration alongside physical stability. While the acidic environment inhibits many pathogens, modern formulations often include additional hurdles against spoilage organisms. The interplay between pH, water activity, and preservative systems creates a multi-barrier approach to food safety without compromising emulsion integrity.

Emerging research explores the potential of alternative emulsifiers to meet various market demands. Plant-based options for vegan mayonnaise, for instance, require different stabilization strategies while delivering comparable sensory qualities. The science of fat emulsification continues to evolve, offering new possibilities for this ancient yet perpetually modern condiment.

From home kitchens to industrial facilities, the principles of emulsion science transform simple ingredients into culinary magic. The next time you scoop a spoonful of creamy mayonnaise, consider the invisible molecular ballet that keeps it perfectly unified - a testament to both nature's ingenuity and human understanding of food chemistry.

By /Jul 14, 2025

By /Jul 14, 2025

By /Jul 14, 2025

By /Jul 14, 2025

By /Jul 14, 2025

By /Jul 14, 2025

By /Jul 14, 2025

By /Jul 14, 2025

By /Jul 14, 2025

By /Jul 14, 2025

By /Jul 14, 2025

By /Jul 14, 2025

By /Jul 14, 2025

By /Jul 14, 2025

By /Jul 14, 2025

By /Jul 14, 2025

By /Jul 14, 2025

By /Jul 14, 2025