The art of yogurt production hinges on a delicate balance of microbial activity, with lactic acid bacteria (LAB) serving as the unseen architects of texture, flavor, and shelf stability. Among the most critical parameters in this biochemical ballet is acidity control—a factor that dictates everything from consumer preference to product safety. While industrial yogurt makers rely on standardized protocols, the underlying science reveals a far more nuanced interplay between bacterial metabolism and environmental conditions.

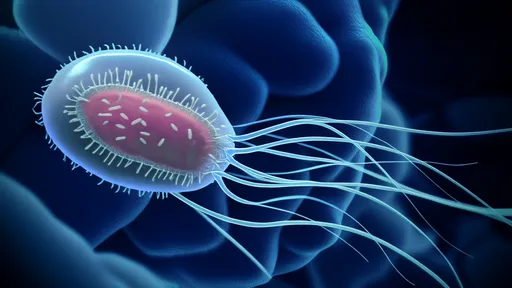

At the heart of yogurt fermentation lies the conversion of lactose into lactic acid by thermophilic strains like Streptococcus thermophilus and Lactobacillus delbrueckii subsp. bulgaricus. This biochemical cascade doesn’t follow a linear trajectory; rather, it unfolds through dynamic phases where bacterial symbiosis creates abrupt shifts in pH. Early-stage fermentation sees S. thermophilus dominate, rapidly acidifying the milk to pH 5.0 before ceding metabolic dominance to L. bulgaricus, which drives the pH down to the target range of 4.0–4.6. This handoff between species isn’t merely chronological—it’s a biochemical relay where each organism’s waste products fuel its partner’s growth.

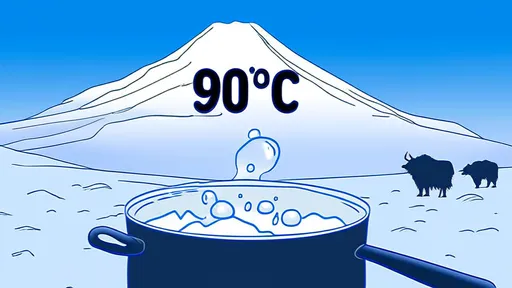

The temperature paradox emerges as a pivotal factor in acidity regulation. While textbook protocols recommend 42–45°C for optimal LAB growth, artisanal producers in the Caucasus Mountains have long manipulated temperatures between 37°C and 43°C to create distinct acidity profiles. Recent metagenomic studies reveal why: sub-40°C temperatures favor Lactobacillus over Streptococcus, resulting in slower but more complex acidification patterns. This explains the tangier notes in traditional yogurts compared to their industrial counterparts, where rushed fermentation at higher temperatures produces sharper, less nuanced acidity.

Milk composition acts as an unsung variable in acidity development. The casein-to-whey protein ratio, often overlooked in commercial settings, creates buffering effects that resist pH changes. Farms producing A2 beta-casein milk report markedly different acidification curves—a phenomenon now attributed to altered peptide release during fermentation. Some European producers have begun blending milks from morning and evening milkings to leverage natural variations in lactose concentration, achieving more consistent acid profiles without post-fermentation adjustments.

Oxygen exposure during fermentation presents another underappreciated lever for acidity control. While LAB are facultative anaerobes, microaerobic conditions (0.5–2.0 mg/L dissolved oxygen) have been shown to boost S. thermophilus activity by 18–22% while slightly inhibiting L. bulgaricus. This creates a self-limiting acidification process where pH stabilizes naturally around 4.3—precisely the sweet spot for many drinking yogurt formulations. Japanese manufacturers have capitalized on this by developing gas-permeable fermentation tanks that maintain optimal oxygen tension throughout the process.

Post-fermentation acidification remains the bane of shelf-stable yogurt production. The industry’s standard solution—thermal inactivation of LAB—often sacrifices flavor and probiotic benefits. Emerging techniques like pulsed electric field (PEF) treatment show promise, with trials demonstrating 85% reduction in post-acidification while preserving viable cultures. Meanwhile, Scandinavian researchers have identified specific bacteriocins produced by certain Lactococcus strains that can inhibit LAB activity at precise pH thresholds, effectively creating a natural "off switch" for acidification.

The future of acidity control may lie in predictive microbiology. By combining real-time pH monitoring with machine learning algorithms, Dutch scientists have developed systems that adjust fermentation parameters dynamically based on the metabolic activity of each bacterial strain. Early adopters report 30% fewer batch variations and the ability to target specific acidity levels with ±0.05 pH unit precision—a degree of control that opens new possibilities for customized yogurt textures and flavors.

From Mongolian airag to Icelandic skyr, traditional fermented dairy products have long embodied the principle that acidity isn’t merely a number—it’s a cultural signature. As modern science deciphers the complex dialogue between lactic acid bacteria and their environment, we’re rediscovering that the most sophisticated acidity control systems may have evolved naturally over centuries of artisanal practice. The challenge for industrial producers lies not in overpowering these microbial ecosystems, but in learning to listen to their subtle biochemical language.

By /Jul 14, 2025

By /Jul 14, 2025

By /Jul 14, 2025

By /Jul 14, 2025

By /Jul 14, 2025

By /Jul 14, 2025

By /Jul 14, 2025

By /Jul 14, 2025

By /Jul 14, 2025

By /Jul 14, 2025

By /Jul 14, 2025

By /Jul 14, 2025

By /Jul 14, 2025

By /Jul 14, 2025

By /Jul 14, 2025

By /Jul 14, 2025

By /Jul 14, 2025

By /Jul 14, 2025