The world of plant-based proteins has witnessed remarkable innovations in recent years, with fermented soybean products occupying a special place in this nutritional revolution. Among these, the unique fibrous texture created through traditional natto fermentation stands out as both a culinary marvel and scientific wonder. This ancient Japanese preparation method, utilizing the powerful Bacillus subtilis natto bacteria, transforms ordinary soybeans into a protein-rich food with distinctive meat-like strands.

At the heart of this transformation lies a complex biochemical process where microbial enzymes systematically break down soybean components and reassemble them into fibrous structures. The natto bacteria secrete a cocktail of enzymes including proteases, amylases, and cellulases that work in concert to modify the soybean's native proteins. What begins as soft, yellowish soybeans gradually develops the characteristic sticky threads and elastic texture that make natto unique among fermented foods.

The protease enzymes play particularly crucial roles in developing the fibrous matrix. These protein-cleaving enzymes target the globular storage proteins in soybeans - primarily glycinin and β-conglycinin - hydrolyzing them into smaller polypeptides and free amino acids. However, the process doesn't stop at simple breakdown. Under the right fermentation conditions, these partially digested proteins realign themselves into parallel, elongated formations that create the filamentous texture. The viscosity comes from poly-γ-glutamic acid (γ-PGA), a natural polypeptide produced by the natto bacteria that acts as a biological glue binding the protein strands.

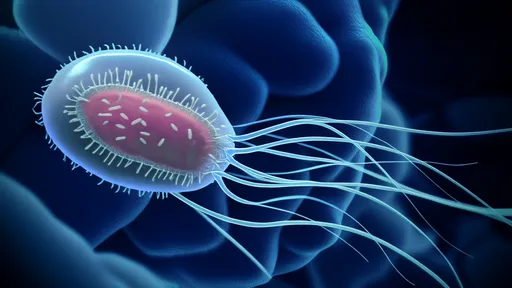

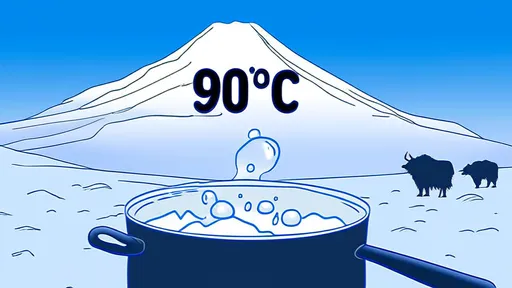

Traditional natto production relies on carefully controlled environmental factors to achieve optimal fiber formation. The beans are typically steamed rather than boiled to maintain structural integrity, then inoculated with Bacillus subtilis natto spores. During the 16-24 hour fermentation at about 40°C (104°F), the bacteria proliferate exponentially, forming a white biofilm on the soybean surfaces. It's during this warm, humid incubation that the magic of fiber formation occurs at the molecular level.

Modern food scientists have isolated the key mechanisms behind this textural transformation. The natto bacteria's enzymatic activity causes partial denaturation of soybean proteins, exposing hydrophobic amino acid residues that would normally remain buried within the protein's three-dimensional structure. These exposed hydrophobic regions then interact with each other, driving the aggregation and realignment of proteins into linear, thread-like assemblies. Meanwhile, the γ-PGA produced by the bacteria forms a viscous network that stabilizes these protein fibers, preventing their random aggregation.

The resulting fibrous structure possesses remarkable mechanical properties that mimic certain qualities of animal muscle tissue. When pulled apart, properly fermented natto can form strands several centimeters long with noticeable elasticity. This texture profile has made natto fermentation an object of study for meat alternative development, as the natural process creates meat-like mouthfeel without mechanical processing or artificial binders.

Beyond texture creation, the fermentation process significantly enhances the nutritional profile of the soybeans. Proteolytic activity increases free amino acids and bioactive peptides, some of which demonstrate ACE-inhibiting properties that may support cardiovascular health. The fermentation also reduces anti-nutritional factors like phytic acid while increasing bioavailability of minerals. Perhaps most notably, natto contains nattokinase, a fibrinolytic enzyme produced by Bacillus subtilis natto that may support circulatory health.

Industrial applications of this biological fiber-spinning process have expanded beyond traditional natto production. Food technologists now utilize controlled natto fermentation to create textured vegetable proteins with varying degrees of fiber orientation and density. By adjusting parameters like fermentation time, temperature, humidity, and bacterial strain selection, manufacturers can tailor the fibrous texture for specific applications - from delicate seafood analogs to hearty beef-like textures.

Recent advancements have explored combining natto fermentation with mild physical processing to enhance fiber alignment. Some methods employ gentle stretching or folding during fermentation to encourage directional fiber formation, while others use specialized containers that influence the growth patterns of the bacterial biofilm. These hybrid approaches allow for even greater control over the final product's textural properties.

The sustainability advantages of this biological texturization method are becoming increasingly apparent. Compared to extrusion or other mechanical methods for creating plant-based meat alternatives, natto fermentation requires significantly less energy input. The process occurs at mild temperatures without need for high-pressure equipment, and the bacterial culture can be maintained with minimal resources. This makes the technology particularly attractive for developing regions seeking affordable protein solutions.

Challenges remain in scaling and standardizing the process for global food production. Variations in soybean cultivars, fermentation conditions, and bacterial strains can lead to inconsistencies in fiber development. Researchers are working to identify molecular markers that predict textural outcomes and developing sensor systems to monitor fiber formation in real-time during fermentation.

Culinary innovators are pushing the boundaries of natto-inspired fibrous proteins beyond traditional applications. Experimental chefs have used controlled natto fermentation to create novel textures in other legumes and even combine multiple fermented proteins to achieve complex, multi-layered textures. Some have explored cold fermentation variants that develop different textural profiles, while others experiment with post-fermentation treatments like smoking or drying to create diverse sensory experiences.

The scientific understanding of this natural fiber-formation process continues to deepen. Recent studies using advanced microscopy techniques have revealed how the protein fibrils organize at nanometer scales, while molecular dynamics simulations help predict how modifications to the fermentation process might alter the final texture. This fundamental research not only improves food applications but also contributes to broader knowledge about protein self-assembly in biological systems.

As consumer demand grows for minimally processed, clean-label meat alternatives, natto fermentation offers a time-tested approach to creating satisfying textures through natural means. The process exemplifies how traditional food wisdom and modern food science can combine to address contemporary nutritional challenges. With its unique combination of cultural heritage, nutritional benefits, and culinary versatility, natto-style fermented fibrous proteins will likely play an expanding role in global diets.

Looking ahead, researchers anticipate further optimization of the fermentation process through strain selection and genetic engineering of Bacillus subtilis natto. By enhancing specific enzymatic activities or introducing new ones, scientists may be able to create even more diverse and sophisticated protein textures. Meanwhile, the growing understanding of how microorganisms can structure plant proteins may inspire entirely new approaches to sustainable food production.

From its humble origins as a traditional Japanese breakfast food to its emerging role in global sustainable nutrition, the story of natto fermentation illustrates nature's remarkable capacity to transform simple ingredients into nutritionally complex and texturally sophisticated foods. As we face the protein challenges of the 21st century, these microbial alchemists - working silently on steamed soybeans - may hold important clues for creating the next generation of plant-based foods.

By /Jul 14, 2025

By /Jul 14, 2025

By /Jul 14, 2025

By /Jul 14, 2025

By /Jul 14, 2025

By /Jul 14, 2025

By /Jul 14, 2025

By /Jul 14, 2025

By /Jul 14, 2025

By /Jul 14, 2025

By /Jul 14, 2025

By /Jul 14, 2025

By /Jul 14, 2025

By /Jul 14, 2025

By /Jul 14, 2025

By /Jul 14, 2025

By /Jul 14, 2025

By /Jul 14, 2025