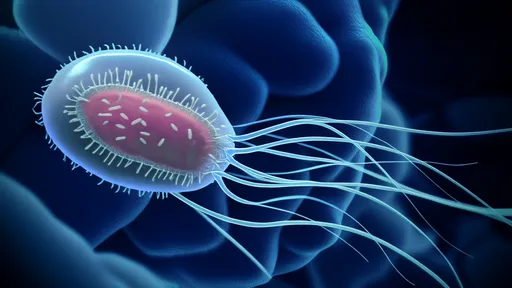

The relationship between yeast gas production, bread volume, and fermentation time is a fascinating intersection of microbiology, biochemistry, and culinary science. For bakers and food scientists alike, understanding this dynamic is crucial for achieving the perfect loaf. Yeast, a single-celled fungus, plays a pivotal role in bread-making by converting sugars into carbon dioxide and alcohol through fermentation. This process not only leavens the dough but also contributes to the flavor, texture, and overall quality of the final product.

When yeast is introduced to dough, it begins to metabolize available sugars, primarily glucose and maltose. The rate at which this occurs depends on several factors, including temperature, pH, and the presence of inhibitors or accelerators. As fermentation progresses, carbon dioxide gas accumulates within the dough, creating pockets that expand the gluten network. This expansion is what gives bread its characteristic volume and airy crumb structure. However, the relationship between gas production and bread volume isn’t linear—it’s influenced by the dough’s ability to retain gas, which is itself a function of gluten strength and fermentation time.

Fermentation time is a critical variable in this equation. Too little time, and the yeast won’t produce enough gas to fully leaven the dough, resulting in a dense, underdeveloped loaf. Too much time, and the gluten may over-relax, causing the dough to collapse or develop off-flavors from excessive alcohol production. The sweet spot varies depending on the type of bread, the yeast strain used, and environmental conditions. For instance, a rustic sourdough might benefit from a long, slow fermentation at cooler temperatures, while a commercial white bread might rely on a faster, warmer rise.

One of the most intriguing aspects of yeast activity is its exponential growth phase. During the first hour or two of fermentation, gas production is relatively slow as the yeast cells acclimate to their environment. But once they enter the log phase, CO2 output increases dramatically. This is why dough often seems to "spring to life" after an initial quiet period. Bakers can observe this visually as the dough doubles or even triples in size. The timing of this expansion is a key indicator of yeast health and activity.

The impact of fermentation time on bread volume isn’t just about quantity—it’s also about quality. Longer fermentation allows for more complex flavor development as byproducts like organic acids and esters accumulate. These compounds contribute to the nuanced taste profiles found in artisanal breads. Additionally, extended fermentation can improve digestibility by breaking down phytic acid and other anti-nutrients present in flour. This is why some consumers find slow-fermented bread easier on the stomach, even if they’re sensitive to gluten.

Modern baking technology has given rise to tools that can precisely measure gas production during fermentation. Devices like rheometers and dough risers provide real-time data on how much CO2 is being generated and how the dough is responding. These insights allow bakers to optimize fermentation schedules for consistent results. For example, a bakery might discover that their ideal bread volume is achieved at the 90-minute mark when the dough has produced exactly 1500 mL of gas per 100 grams of flour. Such precision was unimaginable in traditional baking but is now within reach thanks to advancements in food science.

Interestingly, the relationship between yeast activity and bread volume isn’t just a concern for professional bakers. Home bakers often struggle with inconsistent results because small variations in kitchen temperature or ingredient measurements can significantly alter fermentation kinetics. A dough that rises perfectly in a 75°F kitchen might behave entirely differently at 68°F. This is why many recipes include visual cues ("until doubled in size") rather than strict timetables. Understanding the science behind these processes empowers bakers at all levels to make better decisions and troubleshoot problems more effectively.

Looking ahead, research continues to explore how different yeast strains and fermentation conditions can be manipulated to achieve specific outcomes. Some studies focus on developing yeast varieties that produce more gas at lower temperatures, which could reduce energy costs in commercial bakeries. Others investigate how to enhance the nutritional profile of bread through controlled fermentation. As our understanding of these microbial processes deepens, so too does our ability to harness them for better, more sustainable baking practices.

The dance between yeast, time, and bread volume is a delicate one, but mastering it is what separates good bread from great bread. Whether you’re a scientist studying fermentation kinetics or a home baker perfecting your sourdough starter, appreciating this relationship is key to unlocking the full potential of every loaf. The next time you slice into a beautifully risen piece of bread, take a moment to consider the invisible microbial activity that made it possible—a testament to the power of patience and biological transformation.

By /Jul 14, 2025

By /Jul 14, 2025

By /Jul 14, 2025

By /Jul 14, 2025

By /Jul 14, 2025

By /Jul 14, 2025

By /Jul 14, 2025

By /Jul 14, 2025

By /Jul 14, 2025

By /Jul 14, 2025

By /Jul 14, 2025

By /Jul 14, 2025

By /Jul 14, 2025

By /Jul 14, 2025

By /Jul 14, 2025

By /Jul 14, 2025

By /Jul 14, 2025

By /Jul 14, 2025