The release of aromatic compounds during baking is a complex dance of chemistry and physics, with vanillin playing a starring role. As one of the most recognizable flavor molecules in baked goods, vanillin’s volatility determines how its sweet, creamy notes unfold in the oven and beyond. Understanding its release curve isn’t just academic—it shapes everything from recipe development to industrial food manufacturing.

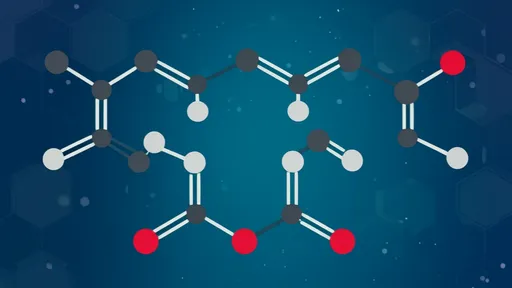

Vanillin’s journey begins when heat destabilizes its molecular structure. Unlike simpler volatile compounds that evaporate rapidly, vanillin’s phenolic ring structure gives it intermediate volatility. During the initial baking phase, moisture content in dough or batter creates a steam-distillation effect, carrying vanillin molecules upward. This explains why the first whiff of baking often carries the most intense vanilla punch—a phenomenon bakers call the "bloom phase."

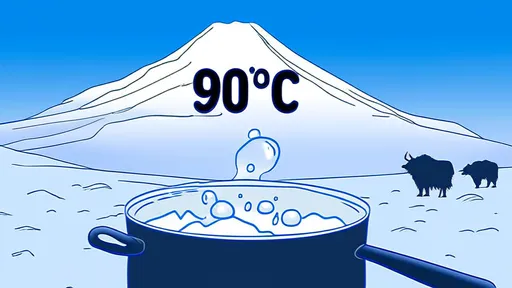

Temperature thresholds dramatically alter vanillin’s behavior. Below 150°C, release occurs gradually as the compound slowly escapes the food matrix. But as oven temperatures climb above this point, the rate of volatilization increases exponentially. Commercial bakers leverage this by employing stepped temperature profiles—starting high to create an initial aromatic burst, then lowering heat to sustain release without burning delicate notes.

The food matrix itself acts as both prison and delivery system. In high-fat recipes like shortbread, vanillin partitions into lipid phases, resulting in delayed but prolonged release. Water-based systems like angel food cake allow faster escape but offer less protection against thermal degradation. Modern pastry chefs are experimenting with emulsion techniques to customize this balance, creating layered vanilla experiences within single products.

Moisture content plays a surprising dual role. While water helps transport vanillin vapor, excessive humidity in the oven environment can actually suppress aroma release through competitive evaporation. This explains why steam-injected artisan breads often have subtler vanilla notes compared to dry-baked cookies, even when using identical vanilla concentrations.

Time is the silent variable in vanillin’s equation. Standard 20-minute bake times only tell part of the story—residual heat continues driving volatilization during cooling. The "carry-over effect" means properly timed removal from the oven allows optimal aroma development as products return to room temperature. Industrial bakers now monitor this through headspace analysis, tracking vanillin concentrations minute-by-minute from oven exit to packaging.

Packaging and storage introduce new dynamics. Unlike fresh-baked goods where vanillin release follows predictable thermal patterns, packaged items face reversed scenarios—the compound’s volatility now causes gradual loss rather than release. Modified atmosphere packaging with nitrogen flushing can reduce this by up to 40%, preserving those precious vanilla notes that took such care to develop.

The human nose perceives vanillin’s volatility differently than instruments measure it. While gas chromatography might show steady decline after baking, sensory panels often report fluctuating intensity due to olfactory adaptation and the compound’s interaction with other aromas. This perceptual complexity explains why some vanilla-forward products taste balanced while others seem to "disappear" flavor-wise despite adequate vanillin content.

Regional baking traditions have unconsciously optimized for vanillin release through centuries of trial and error. French brioche’s egg-rich formula extends aroma perception, while Scandinavian crispbreads’ thin format maximizes immediate impact. Modern bakers are decoding these ancient wisdom, applying the principles to new product development with precision instrumentation.

Future innovations may rewrite vanillin’s volatility rules entirely. Encapsulation technologies now in development could allow timed release at specific temperatures, creating "second wave" vanilla notes hours after baking. Other researchers are engineering yeast strains that produce vanillin precursors which only convert to the aromatic form during consumer reheating—potentially revolutionizing how we experience baked goods’ aroma profiles.

From home kitchens to industrial bakeries, understanding vanillin’s dance with heat transforms baking from routine to revelation. As measurement techniques grow more sophisticated and ingredient technology advances, we’re entering an era where vanilla’s ephemeral magic can be precisely choreographed rather than left to chance.

By /Jul 14, 2025

By /Jul 14, 2025

By /Jul 14, 2025

By /Jul 14, 2025

By /Jul 14, 2025

By /Jul 14, 2025

By /Jul 14, 2025

By /Jul 14, 2025

By /Jul 14, 2025

By /Jul 14, 2025

By /Jul 14, 2025

By /Jul 14, 2025

By /Jul 14, 2025

By /Jul 14, 2025

By /Jul 14, 2025

By /Jul 14, 2025

By /Jul 14, 2025

By /Jul 14, 2025