The sizzle of fish hitting a hot pan is a sound that makes any home cook's mouth water—until the dreaded moment when the delicate skin sticks and tears, leaving behind a culinary disaster. What if the secret to flawless pan-seared fish lies not in fancy techniques, but in the invisible physics of oil molecules? Recent explorations into the science of cooking reveal that a phenomenon called oil film tension creates a protective physical barrier between fish and metal, revolutionizing how we approach this age-old kitchen challenge.

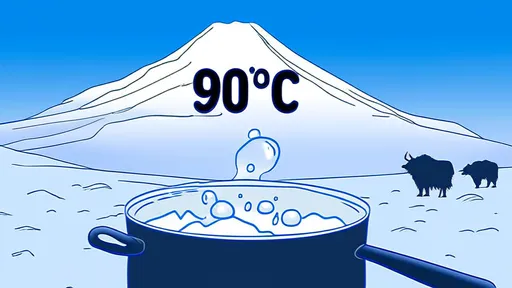

At the heart of this discovery is a deceptively simple principle: when oil heats in a pan, it doesn’t just sit there passively. The molecules undergo dramatic structural changes, aligning themselves into a dynamic, elastic layer. As temperature climbs above 180°C (356°F)—the magic threshold for most cooking oils—these molecules stretch into long chains, forming what physicists call a viscoelastic film. This isn’t merely liquid grease; it’s a temporary shield with measurable tensile strength, capable of gently suspending the fish skin fractions of a millimeter above the pan’s microscopic peaks and valleys.

Chefs have intuitively exploited this phenomenon for generations through the practice of hot pan, cold oil. The thermal shock of room-temperature oil hitting searing metal triggers explosive convection currents, forcing the oil to penetrate every crevice of the pan’s surface almost instantaneously. What most cooks don’t realize is that they’re engineering a microscopic suspension system—the viscoelastic film becomes nature’s non-stick coating, far more effective than any synthetic alternative. When fish skin makes contact, its proteins begin forming bonds not with metal, but with this resilient oil matrix.

The fish skin itself plays an unexpected collaborative role. As collagen fibers contract under heat, they create a natural textured surface resembling a topographical map. Researchers using scanning electron microscopy have found that properly dried fish skin develops microscopic ridges that interlock with the oil film’s structure. This isn’t unlike how tire treads grip wet roads—the textures work in concert rather than opposition. The result? An edible version of the Leidenfrost effect, where violent bubbling actually helps maintain separation between surfaces.

Not all oils perform this high-wire act equally. Through high-speed camera analysis, food scientists have observed that oils with higher smoke points—like refined avocado or peanut oil—form more durable films. The length of their carbon chains allows for greater elasticity, much like how long-staple cotton produces stronger fabric. Meanwhile, delicate extra virgin olive oil’s shorter molecules and plant solids cause premature film collapse, explaining why it’s notorious for sticking despite its gourmet appeal.

The implications extend beyond culinary perfection. Materials scientists are now studying this edible physics lesson for applications in industrial non-stick coatings. Early experiments with synthetic oil-like polymers show promise for creating environmentally friendly alternatives to Teflon. Who knew the humble act of frying fish could inspire the next generation of frictionless surfaces?

Next time you’re tempted to blame your tools for ruined fish, remember: the true guardian against sticking isn’t your expensive pan, but the dancing molecular ballet happening right beneath the fillet. Mastering this invisible barrier requires neither chef’s knives nor Michelin stars—just an appreciation for the beautiful physics sizzling in plain sight.

By /Jul 14, 2025

By /Jul 14, 2025

By /Jul 14, 2025

By /Jul 14, 2025

By /Jul 14, 2025

By /Jul 14, 2025

By /Jul 14, 2025

By /Jul 14, 2025

By /Jul 14, 2025

By /Jul 14, 2025

By /Jul 14, 2025

By /Jul 14, 2025

By /Jul 14, 2025

By /Jul 14, 2025

By /Jul 14, 2025

By /Jul 14, 2025

By /Jul 14, 2025

By /Jul 14, 2025